Have you ever experienced this? You purchase an orthopedic brace, filled with hope that it will alleviate joint pain and provide stable support, only to find it's either painfully tight, cutting off circulation, or frustratingly loose, slipping out of place and offering no protection at all. Have you ever considered that the problem might not be the brace's design, but rather the most fundamental yet overlooked element—its size? An ill-fitting brace isn't just a waste of money; couldn't it potentially worsen your injury?

Can standard S, M, L sizing truly accommodate the unique contours of your individual body? When standardized products fail to meet personalized needs, where do we turn? The answer might be simpler than you think: Go Custom. And when it comes to high-performance orthopedic braces, one material's name consistently rises to the top—Neoprene. So, how can you ensure your custom neoprene brace achieves that "made-for-you" level of perfection?

This ultimate guide will be your one and only map. We will navigate you through every intricate detail of precise measurement, guaranteeing that your next brace fits like a second skin. As a professional manufacturer of neoprene products, we understand that every millimeter of difference has a profound impact on comfort and functionality. Are you ready to bid farewell to those ill-fitting "generic" braces? Let's embark on this journey to the perfect fit together.

Chapter 1: Why Choose Neoprene as the Core Material for Orthopedic Braces?

Before we dive into measuring, we must first understand the material we're working with. Why is neoprene the darling of the world's leading sports and medical brace brands?

1.1 The Golden Triangle of Neoprene Properties: Elasticity, Compression, and Insulation

Neoprene, chemically known as polychloroprene, is a synthetic rubber. Its molecular structure grants it an unparalleled set of physical properties:

Superior Dynamic Elasticity: Think about it. When your joint moves, doesn't a brace need to provide support without restricting your natural range of motion? Neoprene's elasticity perfectly meets this demanding requirement. It stretches and snaps back to its original form, continuously applying even pressure to your joint.

Ideal Compression: Consistent compression is key to promoting blood flow, reducing swelling, and enhancing proprioception (your body's awareness of its position in space). The circumferential pressure provided by neoprene effectively boosts joint stability, giving you more confidence during activity or recovery. Isn't this the sense of security you're looking for?

Excellent Thermal Insulation: Neoprene's closed-cell structure makes it a superb insulator. It traps your body's own heat, gently warming the area around the joint. This therapeutic warmth helps to relax muscles and soothe stiffness and pain. Wouldn't you agree this is a form of natural therapy?

1.2 SBR vs. CR: How Different Grades of Neoprene Affect Your Brace?

You might not know that not all neoprene is created equal. As a dedicated manufacturer, we feel it's our duty to explain the difference, as it directly impacts your brace's performance and longevity.

SBR (Styrene Butadiene Rubber): Often referred to as "SBR neoprene," this is a more economical option. It offers decent elasticity and is the primary material for many consumer-grade sports braces. But can its durability, oil resistance, and weather resistance truly compare to higher-grade materials? For light, everyday protection, it might suffice.

CR (Chloroprene Rubber): This is the genuine, pure neoprene. CR is superior to SBR in virtually every aspect: elasticity, durability, tear resistance, chemical resistance, and aging properties. Why do medical-grade or professional athletic braces insist on CR? Because it delivers the most reliable performance under the most demanding conditions. When you're seeking ultimate protection and a product that lasts, isn't choosing CR the wiser investment?

At NeopreneCustom.com, we are masters of material science. We don't just offer options; more importantly, we recommend the most suitable material based on your specific needs (for instance, post-surgery recovery versus high-impact sports). We accept customizations for all types of neoprene materials, including SBR/CR blends, to strike the perfect balance between cost and performance. Curious to learn more material secrets? Feel free to contact our material specialists anytime at kevin@neoprenecustom.com.

Chapter 2: Pre-Measurement Prep – The Right Tools for the Right Job

Accurate measurement begins with proper preparation. A tiny oversight can lead to a significant discrepancy in the final product. Wouldn't you agree that spending five minutes on preparation is a small price to pay for years of comfortable wear?

Essential Tool: You don't need a rigid ruler. What you need is a soft, flexible tailor's measuring tape. It will conform perfectly to your body's curves, ensuring an accurate reading.

Timing is Everything: Did you know your body's measurements can fluctuate throughout the day? Especially for the lower limbs, there might be slight swelling in the evening after a day of standing and walking. Therefore, we recommend measuring at the same time each day, or if you have issues with joint swelling, measure when the swelling is at its minimum to get the most standard size.

Body Posture: When measuring, keep your body naturally relaxed. Do not tense your muscles. The limb being measured should be in a relaxed, slightly bent position, not locked straight. For example, when measuring the knee, the leg should be slightly bent (about 20-30 degrees). Isn't this posture closest to your state during daily activities?

Marking Points: Use a non-toxic skin marker or a water-based pen to make clear marks at the measurement points. This ensures consistency every time you measure.

Chapter 3: The Ultimate Step-by-Step Measuring Guide by Body Part – The Art of Millimeters

Now, let's get to the core of it. We will explain in detail how to perform precise measurements for each body part. Please remember, the custom services at NeopreneCustom.com are based directly on the data you provide. Your diligence determines the success of the product.

3.1 Knee Brace Measuring Guide

The knee is one of the most complex and easily injured joints in the body. A proper knee brace is crucial.

Core Measurement Point: The center of the patella (kneecap).

Step 1: Locate the Patella Center. Sit down with your leg relaxed and bent. Use your finger to find the movable, circular bone on the front of your knee. Its very center is our reference point.

Step 2: Measure Upper Circumference. From the center of the patella, measure 15 cm (about 6 inches) up your thigh and mark this spot. Then, wrap the measuring tape around your thigh at this mark to measure the circumference. The tape should be snug but not digging into the skin. This measurement is critical for the anti-slip and anchoring function of the brace's top opening, isn't it?

Step 3: Measure Lower Circumference. From the center of the patella, measure 15 cm (about 6 inches) down your calf and mark the spot. Similarly, wrap the tape around your calf at this mark to measure the circumference. This measurement affects the fit of the bottom opening, preventing it from rolling up during use.

Step 4: Measure Knee Joint Circumference. Directly wrap the measuring tape around the center of your patella, measuring the circumference at the most prominent part of the joint. This is the core dimension for the main body of the brace.

Common Mistake: Measuring with the leg locked completely straight or pulling the tape excessively tight. Have you made this mistake before?

3.2 Ankle Brace Measuring Guide

Ankle stability directly impacts your ability to walk and run.

Core Measurement Points: The prominent points of the inner and outer ankle bones (malleoli).

Step 1: Measure Heel-to-Instep Circumference. Place one end of the tape at the bottom of your heel, wrap it diagonally up over the highest point of your instep, and return to the starting point, forming part of a figure "8". This dimension determines the overall envelopment of the ankle brace.

Step 2: Measure Ankle's Narrowest Circumference. About 2-3 cm above the ankle bones, find the narrowest part of your lower leg and measure its circumference horizontally. This affects the fit of the brace's top opening.

Step 3: Measure Arch Circumference. Measure horizontally around the fullest part of your foot's arch. For specific designs that require arch support, this data is indispensable.

Customization Thought: Do you need an open-heel design or a fully enclosed one? Shouldn't the measurement focus differ for different designs? At NeopreneCustom.com, we will discuss these details with you.

3.3 Wrist Brace Measuring Guide

Prolonged keyboard use or strength training can put significant stress on the wrist.

Core Measurement Point: The wrist joint line (the most prominent crease where your palm meets your arm).

Step 1: Measure Wrist Circumference. Simply wrap the measuring tape around the wrist joint line, measuring the circumference at the narrowest point. This is the most basic and crucial measurement.

Step 2: Measure Palm Width (Optional). For braces that need to cover part of the palm, you'll need to measure the width of your palm just below the knuckles (excluding the thumb).

3.4 Elbow Brace Measuring Guide

Whether it's "tennis elbow" or "golfer's elbow," a well-fitting elbow brace can provide effective relief.

Core Measurement Point: The olecranon process of the elbow (the bony tip at the back of your elbow when it's bent).

Step 1: Measure Elbow Joint Circumference. Slightly bend your arm (about 45 degrees) and wrap the tape around the olecranon process to measure the circumference.

Step 2: Measure Forearm's Thickest Circumference. About 5-8 cm below the elbow joint, find the most muscular part of your forearm and measure its circumference.

Step 3: Measure Upper Arm Circumference. About 5-8 cm above the elbow joint, measure the circumference of your upper arm.

3.5 Back/Waist Brace Measuring Guide

Support for the back and waist requires broader coverage.

Core Measurement Point: The navel (belly button).

Step 1: Measure Waist Circumference. Stand up straight and relaxed. Wrap the measuring tape horizontally around your waist, passing over your navel. The tape should remain level and not tilt. This might differ from how you measure for pants, so isn't it important to pay special attention?

Step 2: Measure Hip Circumference (Optional). For longer back braces that extend over the hips, you'll need to measure the horizontal circumference at the fullest part of your hips.

Step 3: Determine Brace Height. How tall do you need the support to be? Measure vertically from the lowest point to the highest point you want the brace to cover. Only custom manufacturing can fulfill this completely personalized dimension, right?

Chapter 4: Beyond Sizing – How We Achieve True "Personalized Customization"

Precise measurement data is the foundation, but true customization goes far beyond that. At NeopreneCustom.com, we pride ourselves on our deep customization capabilities as a manufacturer. We don't just offer a product; we provide a complete solution.

4.1 Customizable Choices for Core Components

A high-quality neoprene brace consists of multiple parts, and you can be involved in the decision-making for each one:

Neoprene Rubber Sponge Core: How thick do you need the material to be? 2mm, 3mm, 5mm, or even 7mm? Thickness directly impacts the level of support and insulation. Do you need CR or SBR? Or perhaps a specific performance blend?

Laminated Fabrics: The inner and outer fabrics determine the brace's feel, durability, and appearance.

Standard Nylon: Durable, economical, and available in various colors.

UBL (Unbroken Loop): A special loop fabric that allows hook-and-loop fasteners to attach anywhere, offering incredible adjustment freedom. Isn't this perfect for braces that require frequent tightening or loosening?

Lycra/Spandex: Silky smooth to the touch, with enhanced elasticity for a luxurious wearing experience.

Medical-Grade Functional Fabrics: We can even provide functional fabrics with antibacterial, far-infrared, or moisture-wicking properties.

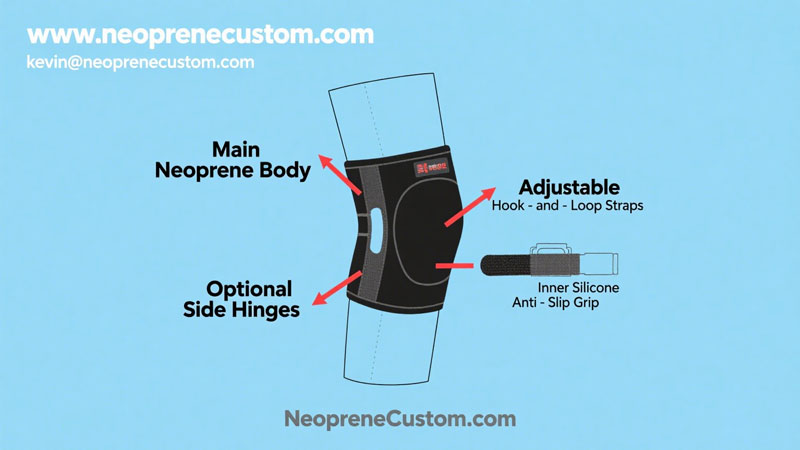

Auxiliary Support and Fastening Systems:

Hook and Loop: The shape, strength, and placement can be customized to your preference.

Hinges: For knee braces that require range-of-motion control, we can integrate metal or plastic hinges.

Silicone Grippers: Adding silicone strips to the inner top edge of the brace effectively prevents it from slipping down. Isn't this a thoughtful little detail?

Spring Stays: Flexible spring stays can be added to the sides of a brace to provide extra lateral support.

4.2 We Are the Manufacturer; We Welcome Your Creative Ideas

As a source factory, our capabilities extend beyond your imagination. Have you ever thought about having your name or team logo printed on your brace, or choosing a one-of-a-kind color scheme? At NeopreneCustom.com, these are not problems. Our production lines are flexible, and our technicians are experienced, ready to turn your design concepts into reality.

From a design sketch to a finished product that meets all your exact needs, we communicate with you every step of the way. You can send your measurement data, functional requirements, or even a rough drawing to us via email at kevin@neoprenecustom.com, and our engineers will provide you with a professional feasibility analysis and a quote. Isn't this the truly "bespoke custom service" you've been searching for?

Conclusion: Stop Settling, Embrace Perfection

Let's return to our initial question: Does your orthopedic brace truly fit? By now, you should understand that a "good enough" answer is simply not enough.

Your joint health deserves the utmost attention and the most precise care. With this ultimate measuring guide, you now hold the key to obtaining a perfectly fitting brace. But this key needs a matching lock—a professional, reliable manufacturer that deeply understands your needs.

NeopreneCustom.com is more than just a website; it's your bridge to comfort, protection, and performance. We invite you to stop compromising and settling for standard sizes. Pick up your measuring tape, follow our guide, and then entrust that unique set of data to us.

It's time to experience a brace that was truly born for you. Visit https://neoprenecustom.com now to browse our customization options, or send your requirements directly to kevin@neoprenecustom.com and let our expert team serve you.

Because your body deserves the very best. Doesn't it?

Contact: Kevin

Phone: 13417385320

Tel: 0734-87965514

Email: kevin@neoprenecustom.com

Add: Intersection of Zhangjialing Road and Science and Technology Road, Guiyang Industrial Park, Guiyang Town, Qidong County, Hengyang City, Hunan Province./Dongguan Factory(Louvcraft): Building 3, No.363 Dongxing West Road Dongkeng, Dongguan.