Are You Specifying Your Industrial Components Correctly, or Just Guessing?

In the intricate dance of industrial design and manufacturing, doesn't every single detail matter? You meticulously plan machinery layouts and process flows, but when it comes to the elastomeric components—the gaskets, seals, and pads—do you apply the same level of precision? Or do you find yourself selecting from a limited catalog, hoping a standard option will suffice? What if you could become an expert in specifying the exact neoprene part you need, ensuring it performs flawlessly from day one?

This guide is your key to unlocking the full potential of custom neoprene. It's designed for engineers, product designers, and procurement managers who refuse to settle for "close enough." As a dedicated manufacturing factory, our goal at https://neoprenecustom.com is to empower you with knowledge. Because when you understand the possibilities of customization, you can demand better. Aren't you ready to move from being a mere buyer to a well-informed design partner?

Step 1: Deconstructing Neoprene - What Are You Actually Customizing?

Before you can specify a custom part, don't you first need to understand the fundamental building blocks? Customizing neoprene isn't just about shape and size. It's a multi-faceted process involving deep material science. When you send your requirements to a specialist manufacturer like us, what variables can you actually control?

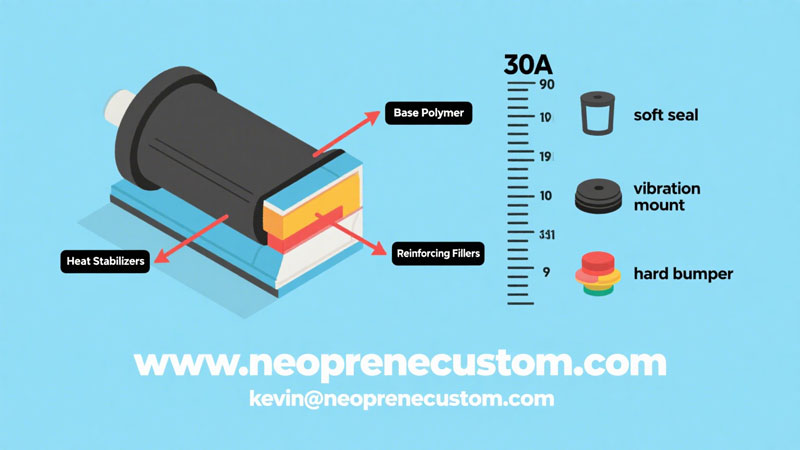

The core of any custom part is the neoprene compound itself. Think of it as a recipe. We, the factory, are the master chefs. You provide the desired outcome (e.g., "a gasket that withstands 150°C and hydraulic fluid"), and we formulate the perfect recipe. This recipe includes:

Base Chloroprene Polymer: The foundation of the material.

Curing Agents (Vulcanization System): Determines how the material sets and its final resilience.

Reinforcing Fillers (e.g., Carbon Black): Enhances strength, abrasion resistance, and durability.

Plasticizers: Controls flexibility and low-temperature performance.

Specialty Additives: This is where we fine-tune for properties like heat resistance, flame retardancy, oil resistance, and UV stability.

Isn't it empowering to know that you're not limited to a single type of "neoprene," but can have a compound engineered specifically for your needs? This is the first and most crucial step. To discuss your unique compound requirements, our chief engineer is available for consultation via kevin@neoprenecustom.com.

Step 2: Specifying Hardness (Durometer) - The Feel and Function

Have you ever wondered what the "Shore A" number on a rubber specification sheet really means? This is the durometer, a measure of the material's hardness or resistance to indentation. Why is this so critical?

Too Soft (Low Durometer, e.g., 30A-40A): The material will be very flexible and conform easily to irregular surfaces, making it ideal for certain types of seals. But could it be too soft to resist pressure and extrude out of a gap?

Too Hard (High Durometer, e.g., 80A-90A): The material will be stiff and highly durable, perfect for abrasion pads or mounting blocks. But will it be too hard to create an effective seal on a non-perfect surface?

The most common range for general-purpose neoprene is 50A to 70A. But what does your specific application demand?

For Sealing: Do you need a softer material (40A-60A) to create a tight seal with low clamping force?

For Impact Absorption: Does your application require a medium-hardness (50A-70A) part to dampen vibration effectively?

For Structural Support: Do you need a very hard material (70A-90A) to act as a durable bumper or spacer?

As a custom manufacturer, we can produce neoprene in virtually any durometer to match your needs. Don't guess; let's define the exact hardness your product needs to succeed.

Step 3: Defining Thickness and Tolerance - Precision Matters

Isn't it obvious that the thickness of a gasket or sheet is important? But have you considered the tolerance? In high-precision applications, a deviation of even a fraction of a millimeter can mean the difference between a perfect fit and a complete failure.

When you work with us at https://neoprenecustom.com, you're working with a factory that understands precision. We can produce:

Neoprene Sheets and Rolls: From paper-thin (e.g., 0.5mm) to exceptionally thick (e.g., 50mm or more), with tight thickness tolerances across the entire sheet.

Molded Parts: For custom shapes, the thickness can vary across the part's geometry, all controlled by a precision-engineered mold.

Why is this level of control so important?

Consistent Clamping Force: A gasket with uniform thickness ensures even pressure distribution.

Predictable Performance: Consistent thickness leads to predictable compression and sealing characteristics.

Interchangeability: Tightly controlled tolerances mean every part you receive from us will be identical to the last.

Can your current supplier guarantee a thickness tolerance of +/- 0.1mm on a custom part? We can. This is the manufacturing precision that sets a specialized factory apart.

Step 4: Choosing the Right Surface Finish - More Than Just Looks

Did you think the surface of a neoprene part was just... rubber? The surface finish can be a critical functional feature, and it's something we can completely customize. What are your options?

Smooth Plate Finish: This is the most common finish, offering a smooth, non-porous surface on both sides. Is this what you need for optimal sealing against flat metal or plastic surfaces?

Fabric Impression Finish: One or both sides can have a textured finish from a fabric liner used during manufacturing. Does your application require a surface that provides a better grip for bonding or prevents sticking?

Cell/Sponge Neoprene: For applications requiring superior compressibility and cushioning, we can produce closed-cell sponge neoprene. Does your application need to seal against light, air, and dust rather than high-pressure liquids?

Fabric Reinforcement: We can bond a layer of fabric (like nylon or polyester) to one or both surfaces. Do you need to dramatically increase the tensile strength and tear resistance for a diaphragm or a heavy-duty strap?

The right finish can enhance performance, improve assembly, and extend the life of your product. Why not leverage this often-overlooked aspect of customization? Send your drawings or ideas to kevin@neoprenecustom.com, and we can recommend the perfect finish.

Bringing It All Together: The Custom Manufacturing Process

So, how do you go from an idea to a finished, high-performance neoprene part? Isn't it reassuring to know there's a clear, collaborative process?

Consultation & Quoting: You contact us with your needs, drawings, or even just a problem you're trying to solve. We discuss the application to understand the requirements for composition, durometer, thickness, and finish.

Material Formulation & Design: Our engineers formulate the perfect neoprene compound and, if needed, help refine the part design for manufacturability.

Tooling & Prototyping: We create the necessary molds or cutting dies. We then produce a first-article prototype for your inspection and approval. Can you be confident without seeing a physical sample first?

Full-Scale Production: Once you approve the prototype, we move to full-scale production in our dedicated factory, under strict quality controls.

Delivery & Support: We deliver your high-quality, custom parts on time and remain your partner for future needs.

Isn't this the kind of thorough, transparent partnership your critical projects deserve?

Don't let the limitations of off-the-shelf products dictate the potential of your designs. Take control. Specify every detail. Partner with a manufacturer who can turn your precise requirements into a physical reality.

Are you ready to design and procure neoprene components with confidence?

Explore the possibilities on our website, https://neoprenecustom.com. For a detailed technical discussion or to start your custom project today, send all specifications directly to our lead expert, kevin@neoprenecustom.com. Let's engineer excellence, together.

Contact: Kevin

Phone: 13417385320

Tel: 0734-87965514

Email: kevin@neoprenecustom.com

Add: Intersection of Zhangjialing Road and Science and Technology Road, Guiyang Industrial Park, Guiyang Town, Qidong County, Hengyang City, Hunan Province./Dongguan Factory(Louvcraft): Building 3, No.363 Dongxing West Road Dongkeng, Dongguan.