Is Your Neoprene Gear Silently Dying? Uncovering the Mystery of Neoprene Cracking and How to Stop It for Good

Have you ever pulled out your favorite wetsuit, a trusted laptop sleeve, or essential medical brace, only to find it covered in a web of unsightly and performance-killing cracks? Does it feel like a betrayal from a material known for its resilience? You're not alone in asking: what on earth causes neoprene to crack, and is there any way to prevent this premature demise?

The answer isn't just a simple "wear and tear." The degradation of neoprene is a complex interplay of chemistry, environment, and care. But what if the real secret to longevity wasn't just in how you store it, but in the very DNA of the material itself? What if you could work directly with a manufacturer to create a neoprene product designed from its core to resist the exact factors that cause it to fail?

This is the very question we help our clients answer every day. As a specialized production factory, we don't just sell neoprene; we engineer custom solutions. Before we delve into how our bespoke services at https://neoprenecustom.com can be your ultimate defense, let's embark on a deep dive into the science of neoprene cracking. Understanding the enemy is the first step to defeating it. For any inquiries about creating a truly resilient product, you can always reach our lead engineer, Kevin, at kevin@neoprenecustom.com.

Chapter 1: Deconstructing Neoprene – What Are We Actually Dealing With?

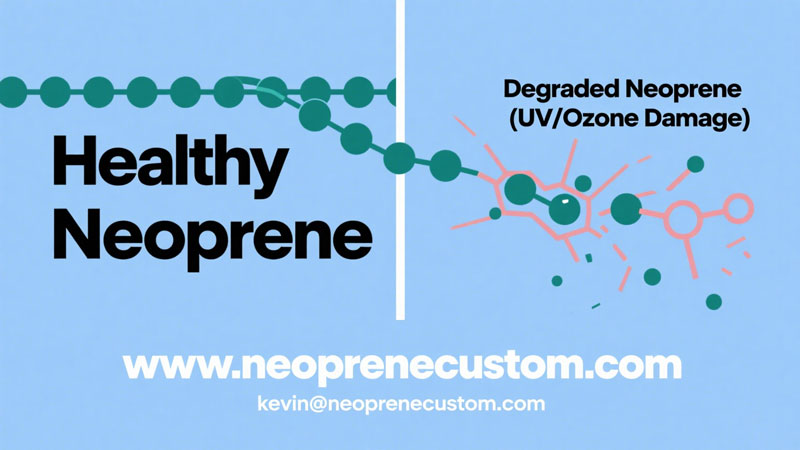

Before we can understand why it breaks, don't we first need to understand what it is? Neoprene is not just a "spongy black rubber." Its technical name is polychloroprene, a synthetic rubber produced by the polymerization of chloroprene. Think of it as a vast, complex chain of molecules all linked together. The specific structure of these polymer chains gives neoprene its celebrated properties: thermal insulation, water resistance, chemical stability, and elasticity.

But did you know there are different grades and compositions?

Chloroprene Rubber (CR): This is the "true" neoprene, offering the best all-around performance in terms of durability, flexibility, and resistance to oil, ozone, and heat. It's the premium choice.

Styrene Butadiene Rubber (SBR): A more cost-effective alternative, often blended with CR. While it has good abrasion resistance and insulation, it typically falls short of CR in terms of UV, ozone, and chemical resistance. This is a common material for promotional items.

CR/SBR Blends (SCR): A middle ground, attempting to balance cost and performance. The ratio of the blend dramatically affects its final properties.

Do you know what your current neoprene product is made of? The very composition is the foundation of its strength or its weakness. A product made from 100% SBR will inherently be more susceptible to cracking from environmental exposure than one made from high-grade CR. This is a critical detail that mass-market producers often obscure. At our facility, we are transparent about these components. We believe the first step to a durable product is choosing the right building blocks, a service we specialize in.

Chapter 2: The Arch-Nemesis Trinity – UV, Ozone, and Oxygen

Why does a material designed for the outdoors seem to be attacked by the outdoors itself? The primary culprits are invisible and relentless: Ultraviolet (UV) radiation, ozone, and oxygen.

1. The Assault of Ultraviolet (UV) Radiation:

Have you ever considered that sunlight, the source of life, is a slow poison for your gear? UV radiation, particularly UVA and UVB rays, is a form of high-energy light. When these photons bombard the surface of neoprene, they act like microscopic wrecking balls. They impart enough energy to break the covalent bonds within the polychloroprene polymer chains. This process is called photodegradation.

Imagine a long, strong chain. Now, imagine a tiny pair of scissors randomly snipping links. The chain becomes shorter, weaker, and less flexible. This is precisely what happens to neoprene at a molecular level. The surface becomes brittle, loses its elasticity, and the first microscopic fissures appear. Over time, these connect and grow into the visible cracks you despise. It starts with a chalky or faded appearance and ends in total material failure.

So, how can you fight back against the sun itself? While storage is key (which we'll cover extensively), doesn't the real solution lie in making the material inherently UV-resistant? This is where a custom manufacturer shines. We can incorporate powerful UV inhibitors and carbon black (a potent UV absorber) directly into the raw neoprene compound. This means your product isn't just hiding from the sun; it's wearing a permanent, molecular-level sunscreen. Interested in this level of protection? Contact us at kevin@neoprenecustom.com to discuss UV-stabilized neoprene formulations.

2. The Silent Attack of Ozone (O3):

Have you ever noticed a "fresh" smell in the air after a thunderstorm? That's ozone, a molecule made of three oxygen atoms (O3). While it forms the protective ozone layer high in the atmosphere, at ground level, it's a highly reactive pollutant generated by electric motors, industrial emissions, and even UV light reacting with pollution.

Ozone is particularly aggressive towards the carbon-carbon double bonds present in most synthetic rubbers, including polychloroprene. It attacks these specific points in the polymer chain, a process known as ozonolysis. This attack severs the polymer chains just as effectively as UV radiation but in a more targeted manner. The result is often a series of deep cracks that appear perpendicular to the direction of stress or stretch in the material. If your neoprene is stored folded or under tension, you might see perfectly parallel cracks forming along the crease.

Isn't it frustrating that an invisible gas can ruin expensive equipment? The defense against ozone, much like with UV, can be built directly into the material. As a custom neoprene producer, we compound our materials with specialized anti-ozonants. These are sacrificial molecules that react with ozone before it has a chance to attack the polymer backbone of the neoprene. It's like having a dedicated bodyguard for the material's structural integrity. This is not a feature you'll find advertised on a generic, off-the-shelf product.

3. The Slow Burn of Oxidation:

Even plain old oxygen (O2) in the air contributes to the aging process, albeit more slowly than UV or ozone. Oxidation makes the neoprene harder and more brittle over a long period. Heat acts as a catalyst, dramatically accelerating this process. Storing neoprene in a hot attic, the trunk of a car, or near a heat source is a recipe for accelerated aging and cracking. This is why you must ask: is my storage environment actively destroying my gear?

Chapter 3: The Mechanical Murderers – Stress, Strain, and Storage Sins

Chemical degradation is only half the story. How you physically handle and store your neoprene is just as critical.

1. The Peril of the Permanent Crease:

Do you fold your wetsuit and stuff it in a bag? Do you leave your neoprene braces bent in a drawer? Every time you fold neoprene, you are creating a point of high stress. The outer edge of the fold is under tension (stretched), while the inner edge is under compression. Leaving it in this state for prolonged periods causes what's known as "compression set" and "stress relaxation."

The polymer chains are physically forced into an unnatural position. Over time, they lose their ability to bounce back. The stretched side becomes weak and thin, and the compressed side becomes dense and hard. When you finally unfold it, the material has been permanently weakened along that line, making it the most likely place for cracks to form, especially when combined with the environmental attacks we just discussed.

How can this be avoided? The answer is simple yet so often ignored: never store neoprene folded. Wetsuits and larger items should be hung on wide, supportive, non-wire hangers. Smaller items like can coolers or laptop sleeves should be stored flat. This simple habit can literally double the life of your product.

2. The Abrasion Annihilation:

Is your neoprene constantly rubbing against rough surfaces? The outer layer of most neoprene products is a laminated fabric, typically nylon or polyester, chosen for comfort and durability. However, constant abrasion can wear through this protective fabric layer, exposing the delicate neoprene foam cell structure beneath. Once the raw foam is exposed, it is significantly more vulnerable to physical tears, UV damage, and chemical attack. Think about the knees and seat of a wetsuit or the corners of a laptop bag. These are high-wear areas.

So, shouldn't the protective fabric be chosen based on the product's intended use? Absolutely. And this is another core aspect of our custom manufacturing process at https://neoprenecustom.com. For a rugged diving suit, we might recommend a highly abrasion-resistant nylon weave. For a fashion tote bag, a smooth, stylish Lycra might be better. We don't believe in a one-size-fits-all solution. We help you choose the right laminate fabric that acts as the first and most important line of defense for the neoprene core.

3. The Contamination Catastrophe: Oils, Solvents, and Chemicals:

Is your neoprene coming into contact with substances other than water? While neoprene is known for its chemical resistance compared to other rubbers, it's not invincible. Petroleum-based products like gasoline, motor oil, and many solvents can penetrate the neoprene and cause it to swell, soften, and lose its structural integrity. Even sunscreen and body oils can slowly degrade the material over time. Chlorine from swimming pools is another harsh chemical that breaks down the material and fades the fabric laminate.

The solution seems obvious, doesn't it? Rinse your gear thoroughly with fresh, clean water after every single use. This is non-negotiable, especially after use in chlorinated pools or saltwater. A deep clean with a specialized neoprene shampoo every few weeks can remove accumulated oils and contaminants.

But what if your application requires contact with specific chemicals or oils? What if you need a neoprene gasket for an industrial machine or a protective sleeve for handling oily parts? This is where standard neoprene fails and custom solutions become essential. We can formulate neoprene compounds with enhanced resistance to specific classes of chemicals. By understanding your exact needs, we can engineer a material that performs reliably in environments that would destroy an off-the-shelf product in days. Do you have such a demanding application? Let's talk. Send your specifications to Kevin at kevin@neoprenecustom.com.

Chapter 4: The Ultimate Prevention Protocol – Your A-to-Z Storage and Care Bible

So, we've dissected the causes. Are you ready for the definitive guide to keeping your neoprene pristine? Following these steps religiously will maximize the lifespan of any neoprene product, but it's especially crucial for standard-grade items.

Step 1: The Post-Use Ritual – The Rinse of Life

This is the most important step. As soon as you are finished using the item, rinse it thoroughly inside and out with cool or lukewarm fresh water. Never use hot water, as it can accelerate the aging of the rubber. Pay special attention to zippers and seams. The goal is to remove all salt, chlorine, sand, and organic residues immediately.

Step 2: The Deep Clean – The Neoprene Spa Day

Every few weeks, or if the item is particularly dirty or smelly, give it a proper wash.

Fill a tub with a large volume of cool water.

Add a capful of a specially formulated wetsuit/neoprene shampoo. Do not use regular laundry detergent, bleach, or harsh soaps, as they will strip the material's natural oils and attack the fabric.

Submerge the item and gently knead and massage it to work the cleaner through the material.

Rinse it multiple times until all soap residue is gone.

Step 3: The Drying Dilemma – The Battle Against Haste

How you dry neoprene is critically important.

NEVER use a machine dryer. The high heat will literally cook the neoprene, making it brittle and causing the seams to delaminate.

NEVER dry it in direct sunlight. As we've established, UV radiation is the number one enemy. Drying it in the sun is like leaving it in a cancer ward.

The Right Way: Hang the neoprene item on a wide, padded hanger (to avoid shoulder stress points) in a well-ventilated, shady area. An airy garage, a covered porch, or a bathroom with a fan works well. Let it drip dry. It may take 24-48 hours. Be patient. Make sure the item is completely dry inside and out before storing it to prevent mildew and bacterial growth.

Step 4: The Storage Sanctuary – The Final Resting Place

Once clean and bone-dry, where should your neoprene live?

The Golden Rule: Store it in a cool, dark, dry place with stable temperature. Avoid attics, basements (if damp), car trunks, and sheds. A closet is ideal.

Hanging is King: For wetsuits, drysuits, and large garments, use a very wide, supportive hanger. This prevents creasing and stress on the shoulder areas. You can buy specialized wetsuit hangers for this purpose.

Rolling, Not Folding: If you absolutely must transport it or cannot hang it, roll it loosely starting from the bottom. Rolling is far less stressful on the material than sharp folds.

Store Flat: For smaller items like laptop sleeves, mousepads, or medical supports, storing them flat is the best option.

Avoid Compression: Do not stack heavy objects on top of your neoprene. This will cause permanent compression of the foam cells and lead to creases.

Isn't it remarkable how a few changes in habit can drastically extend the life of your gear? But it begs the question again: shouldn't a premium product be more forgiving? Shouldn't it be designed to withstand a less-than-perfect world?

Chapter 5: The Custom-Built Fortress – Why Our Neoprene is Different

This brings us to the heart of the matter. You can follow every care guide perfectly, but if you start with an inferior material, you're fighting an uphill battle. What if you could start with a material engineered for victory? This is the philosophy behind our custom manufacturing at https://neoprenecustom.com.

How do we build a better, more crack-resistant neoprene product from the ground up?

1. We Start with Superior Raw Materials:

It all begins with the polymer. We give our clients the choice. Do you need the ultimate durability of 100% CR (Chloroprene Rubber), or does the cost-performance balance of a specific SCR blend make more sense for your project? We provide the data and expertise for you to make an informed choice, not a blind one.

2. We Compound for a Hostile World:

Are you designing a product for intense tropical sun? We will integrate advanced UV inhibitor packages. Is your application in an industrial area with high ozone levels? We will use a powerful anti-ozonant formulation. Will it be used in a garage or workshop? We will select a polymer base with high oil and chemical resistance. We don't just make neoprene; we make application-specific neoprene. We build the solution to your problem directly into the chemical matrix of the material.

3. The Laminate is Part of the Armor:

The fabric on the outside is not just for color. It's the first line of defense. We offer a vast library of laminates:

Super-stretch nylons for high-flexibility applications like performance wetsuits.

Heavy-duty polyester weaves for high-abrasion environments like knee pads or equipment bags.

Smooth-skin or mesh-skin finishes for hydrodynamic or wind-resistant properties.

Printed Lycra for vibrant, custom-branded promotional items.

By matching the right laminate to your product's function, we add a crucial layer of protection against the elements and physical wear that would shred a standard fabric.

4. Precision in Production:

Every step of our process is controlled. The thickness of the neoprene sheet, the lamination process, the type of adhesive used, and the cutting and stitching techniques are all optimized. A poorly laminated sheet can have the fabric peel away, exposing the foam. A bad seam can create a stress point that tears. As a dedicated factory, we control these variables. We are not just an assembler; we are the manufacturer from start to finish.

Are you tired of products that seem designed to fail? Are you ready to create something that lasts, something that reflects the quality of your brand or the seriousness of your application?

This is what we do. We partner with businesses, designers, and innovators to create custom neoprene products. From high-performance athletic gear to rugged industrial components, from stylish consumer products to life-saving medical devices, we provide the material expertise and production capability to bring your vision to life.

Don't let your next project be compromised by generic, off-the-shelf materials. Don't let your customers be disappointed by premature cracking and failure. Take control. Define your requirements and let us build the material to match.

Visit our gallery at https://neoprenecustom.com to see the range of possibilities, or better yet, send your project details directly to our expert, Kevin, at kevin@neoprenecustom.com. Let's build something truly resilient, together.

Contact: Kevin

Phone: 13417385320

Tel: 0734-87965514

Email: kevin@neoprenecustom.com

Add: Intersection of Zhangjialing Road and Science and Technology Road, Guiyang Industrial Park, Guiyang Town, Qidong County, Hengyang City, Hunan Province./Dongguan Factory(Louvcraft): Building 3, No.363 Dongxing West Road Dongkeng, Dongguan.