Neoprene Tear Strength: What Numbers Matter for Heavy-Duty Use

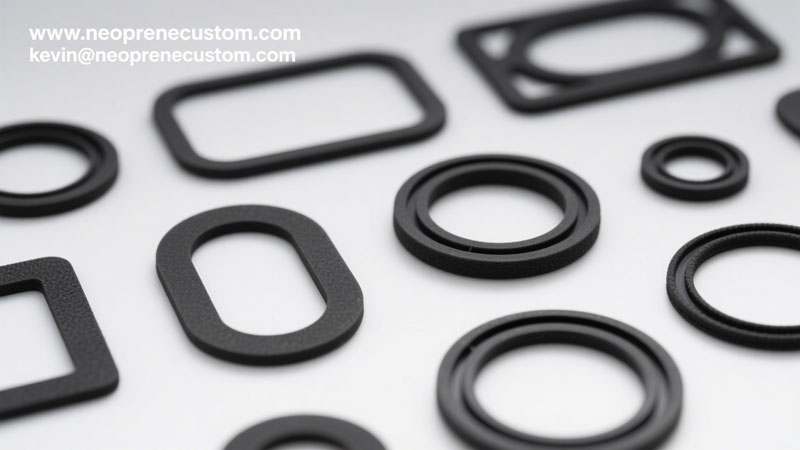

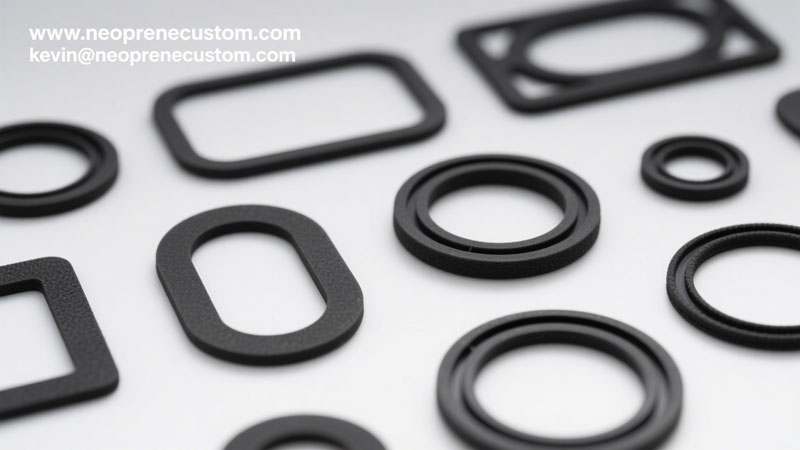

Are you searching for a material that can withstand the toughest conditions without tearing or failing? Whether you’re designing gaskets for industrial machinery, seals for automotive systems, or protective gear for marine environments, neoprene tear strength is a critical factor in ensuring durability and performance. But what numbers really matter when selecting neoprene for heavy-duty applications? At https://neoprenecustom.com, we specialize in crafting custom neoprene products that meet the highest standards for tear resistance, tensile strength, and overall durability. Let’s dive into the key metrics, applications, and why our tailored solutions are the go-to choice for industries worldwide. For inquiries, reach out to kevin@neoprenecustom.com.

What is Neoprene Tear Strength, and Why Does It Matter?

Neoprene, also known as polychloroprene, is a synthetic rubber celebrated for its versatility, chemical stability, and resilience across a wide temperature range. Tear strength, measured in kilonewtons per meter (kN/m) or pounds per inch (lb/in), indicates how much force a material can withstand before a tear propagates. For heavy-duty applications, high tear strength is non-negotiable—it ensures your components endure abrasive environments, mechanical stress, and repeated flexing without failure.

Typical neoprene tear strength ranges from 50 to 100 kN/m for high-performance grades, with premium options like those we produce at neoprenecustom.com reaching even higher values for specialized needs. But numbers alone don’t tell the whole story. The right neoprene for your project depends on factors like durometer (hardness), tensile strength, and environmental resistance, all of which we customize to your specifications.

Key Numbers for Heavy-Duty Neoprene

When evaluating neoprene for heavy-duty use, several metrics stand out:

-

Tear Strength (50–100 kN/m or Higher): According to industry standards like ISO 8067, tear strength measures a material’s resistance to tearing from a pre-cut slit. For heavy-duty applications like conveyor belts, gaskets, or protective coatings, neoprene with tear strength above 50 kN/m is ideal. Our custom neoprene sheets at neoprenecustom.com are engineered to exceed 75 kN/m for maximum durability.

-

Tensile Strength (10–20 MPa or 500–3000 PSI): Tensile strength reflects neoprene’s ability to resist breaking under tension. High-performance neoprene, such as our military-grade options, achieves tensile strengths up to 2500 PSI, making it perfect for demanding industrial and automotive applications.

-

Durometer (20–95 Shore A): Hardness affects how neoprene performs under stress. Softer neoprene (20–50 Shore A) is ideal for flexible seals, while harder grades (60–95 Shore A) suit abrasive environments. We offer customized durometer options to match your needs.

-

Elongation (100–800%): This measures how much neoprene can stretch before breaking. Higher elongation ensures flexibility in dynamic applications like vibration dampening or wetsuits. Our products balance elongation with tear resistance for optimal performance.

-

Abrasion Resistance: Heavy-duty neoprene must resist wear from friction. Our neoprene formulations are tested for excellent abrasion resistance, ensuring longevity in harsh conditions like mining or marine settings.

Why Choose Neoprene for Heavy-Duty Applications?

Neoprene’s unique properties make it a standout choice for industries requiring durability:

-

Chemical Resistance: Neoprene withstands oils, greases, and moderate chemicals, making it ideal for automotive seals and industrial gaskets.

-

Weather Resistance: With excellent UV and ozone resistance, neoprene excels in outdoor applications, from bridge bearings to wetsuits.

-

Flame Resistance: Neoprene’s self-extinguishing properties meet standards like ASTM D2000, perfect for safety-critical applications.

-

Wide Temperature Range (-35°C to 120°C): Neoprene maintains flexibility and strength in extreme conditions, unlike natural rubber.

At neoprenecustom.com, we leverage these properties to create bespoke neoprene products tailored to your project’s demands. Whether you need high tear strength for mining equipment or flexible neoprene for medical braces, we’ve got you covered.

Applications of High Tear Strength Neoprene

Wondering where neoprene tear strength makes a difference? Here are key applications where our custom solutions shine:

-

Industrial Gaskets and Seals: High tear strength neoprene ensures leak-proof seals in machinery exposed to oils, chemicals, and high pressure.

-

Automotive Components: From fan belts to vibration dampeners, our neoprene withstands mechanical stress and environmental exposure.

-

Marine Equipment: Neoprene’s water and UV resistance make it ideal for wetsuits, drysuits, and boat seals.

-

Construction and Infrastructure: Used in bridge bearings and shock-absorbing pads, our neoprene handles heavy loads and vibrations.

-

Protective Gear: Neoprene’s durability and flexibility are perfect for orthopedic braces and safety equipment.

Why Choose neoprenecustom.com?

At https://neoprenecustom.com, we’re not just another neoprene supplier—we’re your partner in creating high-performance, customized solutions. Here’s why industries trust us:

-

Tailored Formulations: We adjustល1 adjust neoprene properties like tear strength, tensile strength, and durometer to meet your exact specifications.

-

Premium Quality: Our neoprene meets or exceeds ASTM, ISO, and military standards for heavy-duty performance.

-

Global Expertise: With years of experience, we serve industries worldwide, from automotive to marine.

-

Direct Support: Have questions? Contact kevin@neoprenecustom.com for personalized assistance.

Our state-of-the-art manufacturing ensures precision and consistency, delivering products that last. Visit neoprenecustom.com to explore our range of neoprene sheets, rolls, and custom components.

How We Ensure Top Tear Strength

Our manufacturing process prioritizes tear strength through:

-

High-Quality Polychloroprene: We use 100% virgin polychloroprene for superior strength and resilience.

-

Advanced Testing: Every batch undergoes rigorous tear and tensile strength testing to meet ISO 8067 and ASTM D2000 standards.

-

Custom Additives: We enhance neoprene with additives for improved abrasion and chemical resistance, tailored to your needs.

Get Started with Your Custom Neoprene Solution

Ready to harness the power of high tear strength neoprene for your heavy-duty applications? At neoprenecustom.com, we make it easy to get the perfect neoprene product. Contact kevin@neoprenecustom.com to discuss your requirements, request samples, or get a quote. Our team is here to deliver durable, reliable, and customized neoprene solutions that stand up to the toughest challenges.