Are You Caught in the SBR vs. CR Dilemma?

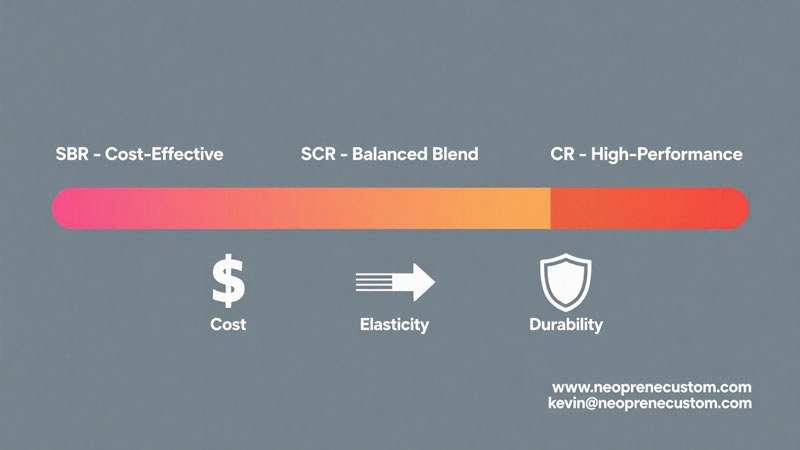

In the world of Neoprene, choices often seem starkly black and white. On one hand, you have SBR (Styrene-Butadiene Rubber)—cost-effective and widely used, but with performance compromises. On the other, there is CR (Chloroprene Rubber)—the gold standard of performance, but with a premium price tag. For countless brand owners, product managers, and designers, isn't this a perpetual challenge? Have you found yourself constantly struggling between the pressure of budget constraints and the ideal of creating a high-quality product? Do you yearn for a material that could possess properties close to CR while offering a price point far more attractive than pure CR?

If your answer is yes, then today, you will find the solution you've been searching for. That solution is SCR.

But what exactly is SCR? Is it truly the fabled "middle ground" that magically combines the price advantages of SBR with the performance highlights of CR? And how does it, through clever material science, infuse your products with unparalleled cost-performance and market competitiveness?

Welcome to this in-depth guide. As a manufacturer deeply rooted in the neoprene industry and dedicated to providing customized solutions for clients worldwide, we will completely unveil the mystery of SCR neoprene for you. We will start from its fundamental chemical composition, meticulously analyze its physical properties, and visually demonstrate its immense potential in real-world applications. This is not just a scientific overview; it's an exploration of a business opportunity. Are you ready to discover this "third option" that could bring a breakthrough for your brand? By the time you finish this article, you might just find that the path to your ideal product has already been paved for you at https://neoprenecustom.com, and the key to unlocking it all could be a simple inquiry sent to kevin@neoprenecustom.com.

Chapter 1: Re-examining the Poles – The Core Values and Limitations of SBR and CR

Before we dive deep into SCR, shouldn't we first clarify the positioning of its two reference points, SBR and CR? It is their distinct characteristics that highlight the value of SCR's existence.

SBR (Styrene-Butadiene Rubber) Foam: The King of Cost-Effectiveness

Core Value: Price. The raw material cost of SBR is significantly lower than CR, making it the top choice for mass-produced, price-sensitive products. From promotional can coolers and mouse pads to entry-level board shorts, SBR is everywhere.

Core Limitation: Performance. As we've discussed in detail previously, SBR falls short of CR in terms of weather resistance (UV and ozone), oil resistance, and long-term water resistance and elasticity. It ages and hardens faster and loses its original shape and function after repeated use. For a company that values brand reputation and user experience, isn't this a potential risk?

CR (Chloroprene Rubber) Foam: The Pinnacle of Performance

Core Value: Performance. CR boasts superior water resistance, elasticity, and durability. It can withstand the harshest environments, providing unparalleled protection and comfort for professional athletes and high-end users. It is the definitive choice for professional wetsuits, premium surf suits, and industrial-grade seals.

Core Limitation: Cost. The high price of CR limits its application scope. For mid-range markets or product lines that require strict cost control, using 100% CR is often impractical.

Thus, a significant market gap emerges: a vast middle ground exists between the "economic affordability" of SBR and the "luxury performance" of CR. The market is in desperate need of a material that can fill this void. And this is precisely the mission for which SCR was born.

Chapter 2: The Birth of SCR – The Art of the Intelligent Blend

What exactly is SCR? Its name itself reveals its identity. SCR stands for Styrene Chloroprene Rubber. It is not a new, independent chemical polymer, but rather a blend of SBR and CR.

How is this "blend" achieved? Is it as simple as gluing two different foams together? Absolutely not.

True SCR material is created at the raw material stage by physically blending the raw rubbers of SBR and CR in specific ratios. Sometimes, this is even achieved through co-polymerization. This uniformly mixed new rubber compound is then put through the exact same foaming and vulcanization processes used to produce pure CR or SBR foam.

This means that on a microscopic level, the rubber matrix of the final SCR foam contains both SBR molecular chains and interspersed CR molecular chains. They intertwine to form a new, composite material system with unique properties.

What is the genius behind this blend?

Imagine you are building a wall.

SBR is like common red brick: cheap and adequate, but not very strong or waterproof.

CR is like high-strength, waterproof granite: incredibly robust, but very expensive.

And SCR? It's like building the wall by embedding a block of granite (CR) every few red bricks (SBR). The overall strength, durability, and water resistance of this wall would be a quantum leap above a pure brick wall, yet its total cost would be far lower than one built entirely of granite.

Isn't this a brilliantly intelligent engineering solution? By precisely controlling the proportion of "granite" (CR) added, you can freely tune the final performance and cost of the wall. And we, at https://neoprenecustom.com, are the "master architects" who have perfected this art of blending. As a professional custom manufacturer, we can precisely formulate different ratios of SCR material for you based on your specific needs, such as:

30% CR / 70% SBR: A very popular and economical SCR formula. It significantly improves the feel, elasticity, and aging resistance over pure SBR, giving the product a much more premium feel with only a marginal increase in cost.

50% CR / 50% SBR: The "golden ratio" that strikes a perfect balance between performance and cost. It provides excellent elasticity and durability, with greatly enhanced water resistance, making it the ideal choice for mid-to-high-end sports supports, quality wetsuits, and durable laptop sleeves.

70% CR / 30% SBR: A high-performance SCR formula. Its properties, especially elasticity and hand-feel, are very close to pure CR, yet it still offers a price advantage over 100% CR. It is suitable for semi-professional products with high performance requirements but slightly limited budgets.

Can you already see the infinite possibilities that SCR brings to your product line? By partnering with us, you no longer have to make a painful, all-or-nothing choice between SBR and CR.

Chapter 3: A Comprehensive Analysis of SCR's Performance – Why It's the "Just Right" Choice

Now, let's delve into SCR's performance metrics to see exactly how it achieves this "just right" balance.

1. Performance-to-Cost Ratio: ★★★★★ (Excellent)

This is SCR's core advantage. It allows you to obtain performance far superior to SBR at a cost far lower than CR. What does this mean for a brand?

You can offer consumers a much higher quality product at a price slightly above SBR products, creating a competitive edge.

You can develop an entirely new mid-range product line, perfectly bridging your existing entry-level and high-end series to cover a broader consumer base.

Your products will have a longer lifespan and better user reviews, thereby enhancing brand loyalty.

In a fiercely competitive market, isn't this superior cost-performance your sharpest weapon?

2. Water Resistance: ★★★★☆ (Excellent)

Pure SBR's weakness in water resistance lies in its substrate's water absorption and poor compression set. When CR molecules are introduced into the SBR matrix, a qualitative change occurs. The CR molecular chains themselves are more hydrophobic. Their inclusion is like building countless tiny waterproof barriers within the SBR molecular network, significantly reducing the water absorption rate of the entire material matrix.

Furthermore, the addition of the CR component also enhances the foam's structural toughness and resilience, allowing it to better recover its shape after compression, thus protecting the integrity of the closed cells. Therefore, while an SCR wetsuit might not match pure CR in extreme deep-sea diving conditions, its water resistance is more than adequate for regular snorkeling, surfing, and other water sports, and vastly superior to SBR.

3. Elasticity & Recovery: ★★★★☆ (Excellent)

This is the improvement that users can feel most directly. Pure SBR feels relatively "stiff," with slower rebound. CR, in contrast, is known for its silky stretch and "memory." Because SCR is blended with CR, its hand-feel and elasticity are dramatically improved.

When your customers pick up a sports support made of SCR, they will immediately feel that soft yet powerful support. When they put on an SCR wetsuit, the snug-but-not-tight, free-to-move feeling will instantly tell them, "This is a high-quality product." Isn't this superior tactile and physical experience a key factor in driving a purchase decision?

4. Durability & Aging Resistance: ★★★★☆ (Excellent)

A major weakness of SBR is its poor resistance to sunlight (UV) and ozone. The chlorine atoms in the CR molecular chain give it natural resistance to aging. In SCR material, these CR molecules act like "preservatives" and "sunscreens" distributed throughout the SBR matrix, effectively slowing down the process of the entire material aging, hardening, and cracking due to environmental factors.

This means that a laptop sleeve made of SCR, even if frequently exposed to sunlight, will not fade and become brittle as quickly as an SBR one would. A surf top made of SCR will still maintain good elasticity and appearance after repeated exposure to seawater and sun. For the consumer, a longer lifespan equals greater value. Are you willing to offer this more enduring value to your customers?

5. Customizability: ★★★★★ (Excellent)

This aspect is the most unique charm of SCR as a blended material and the core value of our service as a professional custom manufacturer.

The performance of pure SBR and pure CR is relatively fixed. The performance of SCR, however, is a dynamic range that can be adjusted on demand. This gives you, the brand owner, unprecedented flexibility.

Want to develop an entry-level wetsuit for the youth market? We can provide you with a 30/70 SCR formula, laminated with brightly colored nylon fabric, to ensure safety and basic performance while keeping costs extremely competitive.

Want to launch a mid-to-high-end knee brace for fitness enthusiasts? We can use the 50/50 golden ratio SCR, laminated with a breathable, super-stretch fabric, to provide the perfect combination of support, comfort, and durability.

Want to add a "flagship" model to your laptop sleeve collection? We can use a high-performance 70/30 SCR, paired with a waterproof zipper and a soft fleece lining, to create a texture and level of protection comparable to premium brands.

At https://neoprenecustom.com, we don't just sell standardized SCR material. We co-create with you. We listen to your market positioning, cost targets, and performance requirements, and then leverage our extensive experience to tailor-make a unique SCR solution just for you. Isn't this deep collaboration and customization the ideal partnership you've been looking for? Send your creative ideas to kevin@neoprenecustom.com and let our chief engineer, Kevin, and his team turn your vision into reality.

Chapter 4: Applications of SCR – The Ubiquitous "Middle Power"

Thanks to its unparalleled balance, SCR has an extremely wide range of applications. It can appear in almost any field where SBR and CR are found, playing the role of a "quality upgrade" or an "economic alternative."

Water Sports Gear: Mid-range wetsuits, surf suits, kayak suits, fishing waders. This is SCR's primary market.

Sports & Medical Supports: Knee braces, elbow guards, wrist supports, waist belts, orthopedic braces. The support, elasticity, and comfort provided by SCR are far superior to SBR.

Consumer Electronics Accessories: High-quality laptop sleeves, tablet cases, camera bags, lens pouches. SCR offers better protection and a more premium feel.

Bags & Handbags: As a material for fashion totes and backpacks, SCR is soft, structured, lightweight, and durable.

Automotive Interiors & Seat Covers: SCR's durability and comfort make it an excellent choice for seat covers and interior trim.

Promotional Gifts: High-end can coolers, bottle sleeves, and cup holders. Using SCR will instantly make your gift stand out from the sea of SBR products.

As you can see, SCR is a ubiquitous "middle power," enhancing the quality and value of countless products in a practical and efficient way. Is your product ready to be empowered by this force?

Conclusion: SCR – Not Just a Compromise, but a Smart Choice

Now, let's return to the original question: SCR neoprene, what makes it a middle ground between SBR and CR?

Through the deep analysis above, we find that the word "compromise" may not be entirely accurate. SCR is not a simple concession; it is a strategic balance, an intelligent engineering choice.

It cleverly draws from the cost advantages of SBR and the performance essence of CR, creating a new, highly cost-effective material solution through scientific blending and proportioning. It provides brand owners with a powerful tool to break the stalemate between cost and performance, develop more competitive products, and meet a wider range of market demands.

For your product, choosing SCR means achieving a leap in quality at a reasonable cost.

For your brand, mastering the application of SCR means having a more flexible product layout and stronger market adaptability.

For your consumers, buying an SCR product means getting an experience that exceeds its value.

So, how do you begin your SCR customization journey?

The answer couldn't be simpler. You don't need an ordinary material supplier; you need an expert partner who deeply understands the essence of SCR and can co-create with you.

At https://neoprenecustom.com, we are that partner. We are a manufacturer specializing in custom neoprene products, particularly adept at precisely blending SBR, CR, and various ratios of SCR according to client needs. We possess advanced production equipment, a strict quality control system, and a creative technical team.

Are you ready to revolutionize your product line with the sharp tool that is SCR?

Do you wish to find a manufacturer who can turn your ultimate pursuit of cost-performance into a reality?

Visit our website https://neoprenecustom.com immediately to explore the successful cases we've built for our global clients. For a more direct approach, send your project requirements, technical questions, or even just a preliminary idea via email to kevin@neoprenecustom.com. Our expert team will provide you with free, professional, one-on-one consulting services and send samples of different SCR ratios for you to experience firsthand, based on your needs.

Stop hesitating between SBR and CR. Embrace SCR, embrace this intelligent balance point, and let's create greater value for your brand together.

Contact: Kevin

Phone: 13417385320

Tel: 0734-87965514

Email: kevin@neoprenecustom.com

Add: Intersection of Zhangjialing Road and Science and Technology Road, Guiyang Industrial Park, Guiyang Town, Qidong County, Hengyang City, Hunan Province./Dongguan Factory(Louvcraft): Building 3, No.363 Dongxing West Road Dongkeng, Dongguan.