When you embark on developing a new wetsuit, a surf top, or any demanding water sports gear, doesn't a critical question constantly loom over your design process: should you use SBR or CR neoprene foam? The market is flooded with conflicting information. Some tout SBR for its cost-effectiveness, while others praise CR as the undisputed king of performance. But when "water resistance" becomes a non-negotiable, top-priority feature, are you truly aware of the vast, chasm-like difference that exists between these two seemingly similar black, stretchy materials? Or more pointedly, what potential risks could choosing the wrong material pose to your brand and, most importantly, to your end-users?

As a manufacturer deeply rooted in the neoprene industry, specializing in high-standard, customized solutions for a global clientele, we feel it is our duty to cut through the noise and empower every product developer to make the most informed decision possible. Today, let's embark on an unprecedentedly deep dive to thoroughly investigate the essential differences between SBR and CR. Are you ready? Let's start at the very root of the matter.

What Exactly is Neoprene, and Why Has It Become the Darling of Water Sports?

Before we can even begin to compare SBR and CR, shouldn't we ask a more fundamental question? What is the scientific nature of this material we casually call "Neoprene"? It is not a naturally occurring substance. Neoprene, known chemically as Chloroprene Rubber, is a synthetic rubber. Its invention was a chemical revolution, with its core component being the polymerization product of chloroprene monomers.

Imagine countless tiny chloroprene molecules joining hands to form long, strong, and flexible chains. This process is called "polymerization." It is this unique molecular structure that endows neoprene with a suite of exceptional physical properties:

Outstanding elasticity and tensile recovery: Ensuring a snug fit and freedom of movement.

Excellent weather and aging resistance: Capable of withstanding sunlight (UV), ozone, and saltwater corrosion.

Good oil and chemical resistance: Far superior to natural rubber.

Crucial thermal insulation (warmth): Achieved by introducing tiny gas-filled bubbles into its structure to form an insulating layer.

And these bubbles, these microscopic pockets of gas, are the very heart of our discussion today. This foaming process is precisely what creates the critical performance gap between CR and SBR. So, how are these two materials actually "made"?

CR Neoprene: The True "King of Waterproofing"—Where Does Its Secret Lie?

CR, an abbreviation for its chemical name, Chloroprene Rubber, is the "authentic" neoprene. It is produced by polymerizing chloroprene monomers in an emulsion, followed by a series of complex processes such as vulcanization and foaming.

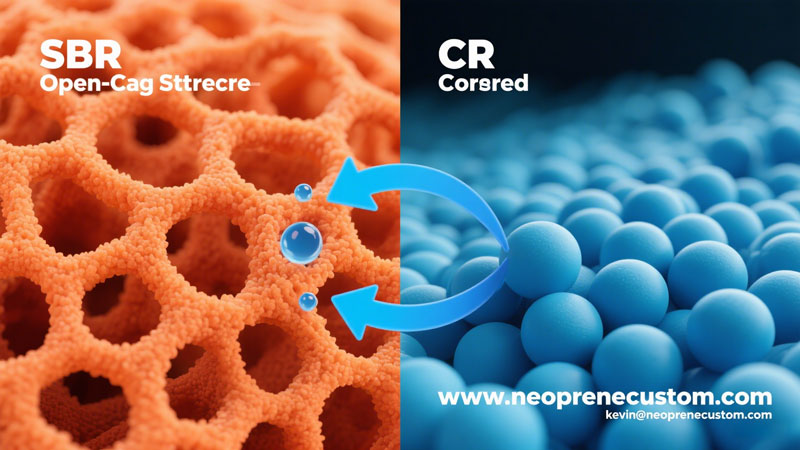

So, why is the water resistance of CR so extraordinary? The answer lies in its microscopic architecture—the Closed-Cell Structure.

Picture the inside of CR foam material as being composed of millions of tiny, independent, completely sealed bubbles filled with nitrogen gas. They are like microscopic, inflated balloons packed tightly together. Each bubble is a discrete unit, with distinct, impermeable walls, completely isolated from its neighbors.

What decisive advantages does this structure provide?

Unparalleled Water Resistance: When water pressure is applied to the surface of CR material, water molecules simply cannot penetrate the interior of these sealed cells. They can only rest on the material's surface or be absorbed by the laminated fabric (if any), but they cannot breach the rubber core. This is precisely why high-end wetsuits, the seals on drysuits, and professional rescue gear unequivocally choose CR. It’s not just "more waterproof"; its physical structure fundamentally dictates its "non-absorbent" nature.

Superior Thermal Insulation: Each closed cell is filled with an inert gas (usually nitrogen), which is a poor conductor of heat. Consequently, CR material forms an incredibly efficient thermal barrier, effectively preventing body heat loss and providing sustained warmth even in frigid waters.

Higher Structural Strength and Compression Recovery: The independent cell structure allows CR material to quickly bounce back to its original shape after being compressed, resisting permanent indentations (compression set). This is vital for wetsuits that undergo repeated wearing, folding, and pressure, directly impacting the product's lifespan.

Superior Chemical and Weather Resistance: The inherent chemical stability of the CR polymer chain, combined with its closed-cell structure, elevates its resistance to saltwater, chemicals, UV radiation, and ozone to the highest level.

So, if someone asks you, "Is CR neoprene truly waterproof?" You can answer with absolute confidence: Yes, its closed-cell structure fundamentally eliminates water absorption, making it the gold standard for waterproof and thermal performance among commercial elastomers.

SBR Neoprene: The Cost-Effective Challenger, But How Reliable Is Its "Waterproof" Promise?

Now, let's turn our attention to SBR. The scientific name for SBR is Styrene-Butadiene Rubber. As the name suggests, its primary chemical components are styrene and butadiene, not chloroprene. Strictly speaking, it isn't "neoprene" at all. However, because its appearance and some of its properties are similar to neoprene, and it is often blended with it, the industry has come to call it "SBR neoprene" or "SBR Neoprene."

What, then, is the microscopic structure of SBR? Herein lies the crux of the issue. Most commercial-grade SBR foam materials utilize an Open-Cell or Semi-Open-Cell Structure.

Engage your imagination once more: the interior of SBR foam is more akin to a sponge. The tiny bubbles within are interconnected, forming a complex network of channels.

What does this open-cell structure imply?

Inherent Water Absorption: This is SBR's "Achilles' heel." When SBR material is submerged in water, water will gradually seep into the material's core through these interconnected pathways, much like a sponge soaking up liquid. While the process may not be instantaneous, over time and with increased water pressure (such as when diving to depth), the material becomes progressively heavier and waterlogged.

Diminished Thermal Performance: Once water infiltrates the material, it displaces the air/nitrogen that was providing insulation. Water conducts heat 25 times more efficiently than air! This means a waterlogged SBR material will rapidly conduct your body heat away, causing a dramatic drop in its insulating capability. For an athlete in cold water, this can be extremely dangerous.

Lower Rebound and Durability: The open-cell structure is more susceptible to being "crushed" under repeated compression and struggles to fully recover. Consequently, products made from SBR generally have a shorter lifespan and poorer performance retention compared to those made from CR.

The Cost Advantage: So why is SBR still so prevalent? The answer is simple: cost. The raw materials and production processes for SBR are significantly cheaper than those for CR. This makes it a highly attractive option for many applications where extreme water resistance is not the primary concern and cost is a major driver.

Therefore, when the question returns to "How is the water resistance of SBR?", the answer becomes nuanced. It possesses a degree of "water repellency" and can fend off brief splashes. But when used in applications requiring prolonged immersion, such as wetsuits, its "waterproof" promise becomes unreliable. It will absorb water, it will get heavy, and it will lose its warmth.

SBR vs. CR: A Head-to-Head Battle in Wetsuit Applications—Is There Really Any Contest?

Let's now place both materials in the same arena, with the goal of "manufacturing a top-tier wetsuit," for a comprehensive comparison.

| Feature | CR (Chloroprene Rubber) | SBR (Styrene-Butadiene Rubber) | Significance for Wetsuit Application |

| Water Resistance | Excellent (Closed-Cell) | Poor (Open/Semi-Open Cell) | THE CORE DIFFERENCE! CR keeps the user dry and light; SBR absorbs water, becoming heavy and burdensome. |

| Thermal Insulation | Excellent (Trapped Gas) | Fair (Plummets when wet) | CR provides consistent, reliable warmth; SBR can accelerate heat loss once saturated, posing a safety risk. |

| Durability/Rebound | Very High | Medium | CR wetsuits last longer and resist packing out; SBR may show compression marks and performance decay faster at joints. |

| UV/Ozone Resistance | Superior | Fair | CR better withstands sun exposure and harsh outdoor conditions, extending product life. |

| Flexibility/Elasticity | Excellent | Good | Both are flexible, but high-grade CR can offer better stretch and a more ergonomic fit at equivalent durometers. |

| Cost | High | Low | This is SBR's only clear advantage and why it's chosen for entry-level or non-critical water gear. |

The verdict is self-evident, isn't it? For any serious wetsuit, surf suit, or other high-performance water sports apparel where water resistance and warmth are paramount, CR neoprene is the one and only correct choice. To use SBR is, in essence, to trade user safety and comfort for a marginal cost saving. Is that a trade-off you're willing to make?

Beyond Black and White: The Power of Customization—This Is Where a True Manufacturer Shines!

At this point, you might be thinking, "Okay, I get it, CR is the way to go. But does this mean all my products must use the most expensive, 100% CR material?"

This is precisely the kind of question a savvy product developer would ask, and it's exactly where we—**Neoprene Custom (https://neoprenecustom.com)**—demonstrate our value. We are not mere material traders; we are neoprene solution manufacturers and engineers. We understand that real-world product development is a constant quest for the optimal balance between performance, cost, and market positioning.

Did you know that the world of neoprene is far more vibrant and nuanced than just "SBR vs. CR"?

CR/SBR Blended Foams: We can fine-tune the blend ratio of CR and SBR according to your specific requirements. For instance, a casual snorkeling vest for warm waters might benefit from a 70% SBR / 30% CR blend, achieving a significant cost optimization while maintaining essential performance. Want to discover the golden ratio for your product? Contact our expert, Kevin, at , and he will provide professional formulation advice.

Different Grades of CR: CR itself comes in various grades. From top-tier, Japanese-made limestone-based CR (a more eco-friendly option) to high-quality Taiwanese CR and standard mainland China CR, their performance and price points vary. We can offer you all these options and explain their subtle differences to help you target your market precisely. Have you heard about limestone neoprene? It's greener than traditional petroleum-based CR, with a more uniform cell structure, leading to enhanced warmth and elasticity. Looking for a new selling point for your premium, eco-conscious product line?

Functional Fabric Laminations: The raw neoprene foam (which we call "sponge") is not very abrasion-resistant and is typically laminated with fabric on one or both sides. Have you ever considered how much the choice of fabric impacts the final product's performance?

Nylon Jersey: Provides durability and good elasticity.

Super Stretch Fabric: Offers 4-way stretch for ultimate freedom of movement, a standard for high-end wetsuits.

Abrasion-Resistant Fabrics (Kevlar, Supratex): Used for reinforcing high-wear areas like knees and elbows.

Thermal Fleece Lining: Laminated on the inside, it traps more air and provides a comfortable, soft feel against the skin, further boosting insulation.

We accept custom lamination with any fabric! You can specify the color (just provide a Pantone number), texture, or even supply your own proprietary functional fabric. At https://neoprenecustom.com, we can turn your vision into reality.

Thickness and Finishing: Do you need an ultra-thin 1mm sheet for a triathlon suit, or a thick 10mm slab for deep-sea diving? We can precisely slice our neoprene sponge to any thickness you require (with a tolerance of ±0.2mm). Furthermore, we offer post-processing services like embossing, perforation, and printing to make your product stand out both functionally and aesthetically.

Why Choose Us as Your Custom Manufacturing Partner?

You might ask, with so many suppliers out there, why are we your ideal choice?

Because we offer more than just a product; we provide a complete solution and a professional commitment. When you email Kevin at kevin@neoprenecustom.com, you won't just get a price list from a salesperson. You will receive a consultation from an experienced material engineer.

We Are the Source Factory: We control every step of the process, from foaming and slicing to lamination and finishing. This means no middlemen, ensuring you get the most competitive pricing. More importantly, our quality control is end-to-end, guaranteeing that every batch of material meets your stringent standards.

We Understand Your Product: We don't just know the chemical and physical properties of our materials; we understand how those materials will be used in your final product. We will ask you: "What water temperature is your wetsuit designed for? Is your target user a beginner or a professional? What are your most critical performance metrics?" Based on these questions, we can recommend a solution that is truly "right," not just "expensive."

We Embrace Extreme Customization: We offer flexible MOQs and rapid sample development. Whether you need a color that has never been seen before, a special multi-layer composite structure, or an embossed pattern featuring your brand's logo, we have the capability and the willingness to make it happen. Your innovation is our mission.

We Promise Transparency and Professionalism: We will candidly explain the drawbacks of SBR and the benefits of CR, detail the differences between various grades of CR, and provide comprehensive physical property data sheets. We believe that a business relationship built on trust and expertise is the one that lasts the longest.

Conclusion: Stop Letting the Wrong Choice Devalue Your Product

Let's circle back to our original question: SBR vs. CR neoprene, which is better for a wetsuit that demands superior water resistance?

The answer is clear and unequivocal: CR (Chloroprene Rubber), with its closed-cell foam structure, is the only choice for achieving true waterproofing, efficient insulation, and long-lasting durability.

Choosing SBR is choosing a material that will absorb water, compromise warmth, and negatively impact the user experience. For a brand dedicated to creating high-quality water sports gear, this is akin to building a house on a flawed foundation.

So, the next time you're designing a product, don't ask, "Should I use SBR or CR?" Instead, ask, "What grade of CR do I need? What functional fabric should I pair it with? How can I leverage a custom material solution to create a star product that is unique in the market and surpasses my competitors?"

The answers to those questions are right here with us.

Don't hesitate, and don't compromise. Visit our official website, https://neoprenecustom.com, to browse our extensive capabilities. Or, send your concepts, questions, or even your preliminary design sketches directly to our material expert, Kevin, at his email: kevin@neoprenecustom.com.

Let's work together to build the most exceptional products with the most professional materials. Because your success is our greatest achievement.

Contact: Kevin

Phone: 13417385320

Tel: 0734-87965514

Email: kevin@neoprenecustom.com

Add: Intersection of Zhangjialing Road and Science and Technology Road, Guiyang Industrial Park, Guiyang Town, Qidong County, Hengyang City, Hunan Province./Dongguan Factory(Louvcraft): Building 3, No.363 Dongxing West Road Dongkeng, Dongguan.