Is your brand searching for a surfboard traction pad that truly embodies its professional image? Are you tired of the generic, one-size-fits-all products flooding the market? When your customers are pushing their limits on the crest of a wave, can that piece of foam under their feet truly provide fail-safe grip and the perfect sensory feedback? It's more than just a simple foam pad, isn't it? It is the most critical link between the surfer and the board, the source of confidence for every turn, takeoff, and aerial maneuver. So, what is the core of the issue? What material can perfectly balance the ferocious grip required for extreme sports with the comfortable foot feel sought after during long sessions?

The answer, perhaps, lies in a material often mentioned but rarely understood in depth: SBR (Styrene-Butadiene Rubber) foam. As a manufacturer deeply rooted in the R&D and production of specialized foam materials, we want to use this article to explore with you why SBR foam is the "golden partner" for surfboard traction pads, and how we, with our expert craftsmanship, can create a unique, fully customized SBR surfboard traction pad for you.

I. Unveiling the Mystery of SBR Foam: What Exactly Is It?

When people discuss surfboard traction pads, EVA (Ethylene-Vinyl Acetate) is often the first name that comes to mind. But have you ever considered if a superior option exists for more demanding performance applications? SBR, short for Styrene-Butadiene Rubber, is a synthetic rubber renowned for its excellent abrasion resistance, anti-aging properties, and superior elasticity and stability compared to natural rubber. When SBR is processed into a closed-cell foam structure, its physical properties exhibit astonishing potential.

Isn't this just another type of rubber? What is the fundamental difference between it and the common EVA?

The molecular structure of SBR foam endows it with a unique "memory" function. When compressed, it provides adequate cushioning; when the pressure is released, it quickly rebounds to its original shape, unlike some low-density EVA foams that are prone to permanent indentations. What does this property imply? It means your customers receive consistent, stable support with every single stomp. We, as a specialized manufacturer, can precisely control the density, hardness, and rebound rate during the SBR foaming process. Isn't this the first crucial step toward achieving the "ideal foot feel"?

Our R&D center, featured on https://neoprenecustom.com, houses a library of dozens of different SBR material formulas. We don't just purchase generic materials from the market; we adjust the ratio of butadiene and styrene from the source, based on the specific application scenario of the product, thereby creating SBR foams with distinct performance characteristics. Curious about which formula is best suited for your product line? Feel free to contact our material engineer, Kevin, at kevin@neoprenecustom.com anytime.

II. The Performance Showdown: SBR Foam vs. Traditional EVA - Where Are the Advantages?

Choosing a material is like choosing armor for a warrior; it must be precisely matched to the demands of the battlefield. Surfing, a sport accompanied by water, sun, and intense friction, places extremely harsh demands on traction pad materials. So, in this performance showdown, how does SBR stand out?

Grip: Is "Non-Slip" Merely Enough?

Of course not. True grip is a dynamic, controllable friction. The grip of EVA pads primarily comes from their surface groove patterns. But have you noticed that when the EVA surface wears down or at certain extreme water temperatures, its grip performance diminishes significantly?

The advantage of SBR foam lies in its intrinsic microscopic surface structure. It possesses a naturally higher coefficient of friction. Even when completely wet, the molecular-level "tackiness" of SBR provides an extra layer of security. More importantly, through our unique surface treatment processes, such as Diamond Groove, Brushed Finish, or the more aggressive Square Groove textures, we can elevate the physical grip of SBR to a new dimension. These grooves aren't just pressed on; they are deeply integrated with the SBR material itself, forming a multi-directional, three-dimensional anti-slip matrix. Have you ever thought about providing your customers with a feeling of being "locked in" to their board in any stance? We are the experts at achieving this.

Foot Feel & Cushioning: Rock Hard or Mushy Soft?

Neither. The ideal foot feel is a perfect combination of support and cushioning. A pad that's too hard will cause foot fatigue from vibrations, while a pad that's too soft will absorb too much energy, making the surfer feel "disconnected" from the board.

SBR foam, especially our custom medium-density formula, offers a unique "progressive cushioning" experience. Under light pressure, it provides firm support, allowing the surfer to clearly feel the board's dynamics. During high-impact maneuvers like landing an air, the closed-cell structure of SBR effectively absorbs and disperses the impact force, protecting the ankles and knees. Isn't this precisely the "one with the board" state that professional surfers strive for? We can precisely adjust the Shore hardness of the SBR based on your brand's positioning (e.g., targeting competitive athletes versus recreational surfers) to create your signature foot feel.

Durability: How Long Should a Traction Pad Last?

Do your customers complain about their pads peeling at the edges, the surface wearing smooth, or the material hardening and cracking after just one season? This is typically a sign of insufficient material weather resistance.

SBR demonstrates superior performance over standard EVA in terms of abrasion resistance, UV resistance, and saltwater corrosion resistance. The SBR traction pads we manufacture have specific anti-UV agents and antioxidants added to their formula, ensuring they maintain their original elasticity and color under the tropical sun and constant saltwater immersion. The adhesive we use is a rigorously selected 3M marine-grade special adhesive, guaranteeing an ultra-strong bond to the surfboard surface and eliminating the annoyance of peeling edges. Wouldn't you want to offer your customers a reliable "install once, use for seasons" product? At https://neoprenecustom.com, quality and durability are our non-negotiable commitments.

III. Customization: From Concept to Reality, How We Build Your Exclusive Traction Pad

As a source manufacturer, our greatest advantage lies in our ability to provide a complete, from-scratch customization service. This is far beyond simple private labeling. Have you ever had a brilliant design concept but struggled to find a factory capable of bringing it to life?

Shape & Structure:

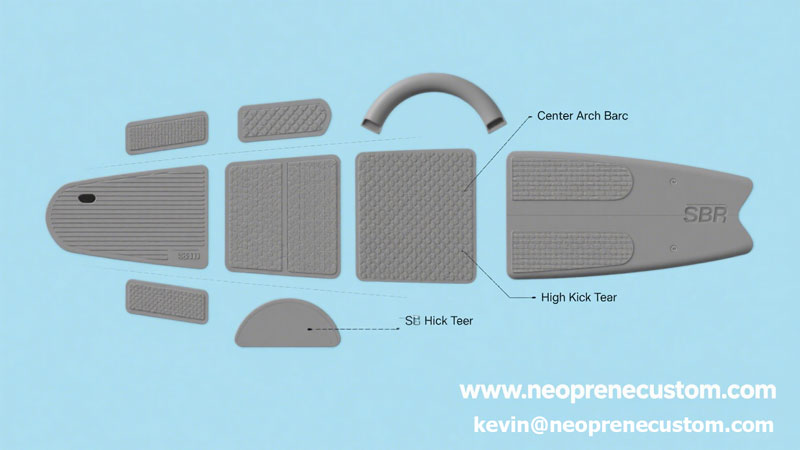

Do you need a large one-piece pad for maximum coverage, or a multi-piece set for a fishtail or longboard? Do you desire a higher, steeper Tear Drop arch bar for support, or an extra-high kick tail for ultimate turning leverage? We have advanced CNC cutting equipment that can achieve precise cuts of any complex shape based on your CAD drawings.

Material & Density:

We can provide pure SBR, pure EVA, or even composite materials foamed with a specific blend ratio of SBR and EVA. Want to use high-density SBR in the heel area for enhanced support and a slightly softer material in the toe area for comfort? No problem. We can achieve seamless multi-density material splicing.

Color & Logo:

Beyond the standard black, white, and gray, we offer Pantone color matching services. For your brand logo, do you prefer a debossed effect achieved through CNC engraving, or a colorful design via screen printing or heat transfer? Or even creating your logo by inlaying different colored SBR pieces like a puzzle? We can do it all.

Surface Texture:

From classic diamond and corduroy grooves to our exclusively developed biomimetic texture that mimics shark skin, we have over 30 texture molds for you to choose from. Or perhaps you have a brand-new texture idea? Our mold engineers can create a new mold for you.

Does this all sound complicated? It's actually very simple. You just need to communicate your ideas to our specialist, Kevin, at kevin@neoprenecustom.com, and he will guide you through the entire process from design prototyping to mass production. We believe that a powerful brand's every detail should radiate unique charm.

IV. Beyond the Product: Why Choose Us as Your Partner?

In this industry, there are many factories that produce traction pads, but partners who truly understand materials, surfing, and branding are rare. Your choice should not be just a supplier, but a technical partner who can grow with you.

Who are we? We are https://neoprenecustom.com, a team composed of material scientists, structural engineers, and passionate surfers. Our passion lies in exploring the possibilities of new materials and transforming them into outstanding products that enhance athletic performance.

We are the direct manufacturer: No middlemen means you get more competitive pricing and faster response times.

We embrace deep customization: Our Minimum Order Quantity (MOQ) is flexible. We are willing to grow with startup brands and have the capacity to serve major international labels.

We promise quality: From raw material inspection to finished product shipment, we have over 15 quality control checkpoints to ensure every single pad meets the highest standards.

Conclusion: It's Time for a Change

Are you going to continue to struggle in a market of homogenized products? Don't you want to inject your brand with a core competitive advantage based on technology and performance? The SBR foam surfboard traction pad is not just an upgrade; it represents an uncompromising attitude towards performance and quality.

Choosing SBR means choosing superior grip, enhanced comfort, and long-lasting durability. And choosing us means choosing a professional manufacturing partner who can turn all your visions into reality.

Are you ready to equip your surfboards with their true "golden partner"?

Visit https://neoprenecustom.com now to browse our case studies, or send your requirements directly to kevin@neoprenecustom.com to begin your exclusive customization journey.

Contact: Kevin

Phone: 13417385320

Tel: 0734-87965514

Email: kevin@neoprenecustom.com

Add: Intersection of Zhangjialing Road and Science and Technology Road, Guiyang Industrial Park, Guiyang Town, Qidong County, Hengyang City, Hunan Province./Dongguan Factory(Louvcraft): Building 3, No.363 Dongxing West Road Dongkeng, Dongguan.