Have you ever wondered what sets high-quality neoprene sheets apart from the rest? At neoprenecustom.com, we pride ourselves on delivering custom neoprene solutions that meet the highest industry standards. Whether you’re in automotive, marine, fashion, or medical industries, our neoprene sheets are engineered for durability, flexibility, and performance. But how do we ensure every sheet is perfect? It all comes down to our meticulous 7-step quality control process. Let’s dive into how we craft the best neoprene sheets and why you should partner with us for your next project.

Neoprene, a synthetic rubber known for its flexibility, water resistance, and durability, is a go-to material for countless applications. From wetsuits to gaskets, medical braces to industrial seals, neoprene sheets are prized for their ability to withstand harsh conditions while maintaining performance. But not all neoprene is created equal. Inferior materials can crack, fade, or fail under stress. That’s why our team at neoprenecustom.com specializes in custom neoprene sheets, tailored to your exact specifications. Curious about how we guarantee perfection? Our 7-step quality control process is the answer.

What’s the foundation of a perfect neoprene sheet? It starts with the raw materials. We source only the highest-grade chloroprene rubber and additives from trusted suppliers. Each batch is tested for purity, elasticity, and chemical composition to ensure it meets our strict standards. By controlling the quality from the very beginning, we lay the groundwork for neoprene sheets that perform flawlessly in any application.

Ever wondered how neoprene can be tailored for specific needs? Our compounding process is where the magic happens. We blend raw materials with precise additives to achieve the desired thickness, flexibility, and resistance properties. Whether you need neoprene sheets for extreme temperatures or waterproof applications, our team customizes the formula to match your requirements. This step ensures that every sheet we produce at neoprenecustom.com is unique to your project.

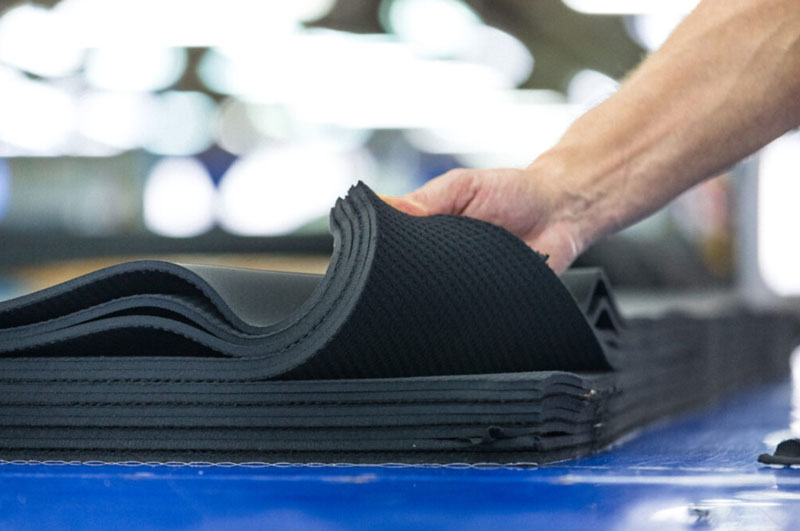

How do we achieve uniform thickness and texture? Our state-of-the-art mixing and calendering machines ensure that every neoprene sheet is consistent. The rubber compound is carefully mixed to eliminate air bubbles and impurities, then passed through rollers to create sheets of precise thickness. This process guarantees that our neoprene sheets are smooth, durable, and free of defects.

What makes neoprene sheets so tough? Vulcanization is the key. During this step, we heat the neoprene under controlled conditions to enhance its strength, elasticity, and resistance to environmental factors like UV rays, chemicals, and water. Our advanced vulcanization process ensures that every sheet meets the highest standards for durability, making them ideal for demanding applications.

How do we know every sheet is perfect? We test, test, and test again. Each batch of neoprene sheets undergoes rigorous quality checks, including tensile strength, elongation, tear resistance, and water absorption tests. We also inspect for visual defects like cracks or inconsistencies. Only sheets that pass our strict criteria move on to the next step. This commitment to quality is why industries worldwide trust neoprenecustom.com for their neoprene needs.

Need neoprene sheets in specific shapes or sizes? Our precision cutting and finishing process ensures that every sheet is tailored to your exact specifications. Using advanced CNC machines, we cut neoprene with pinpoint accuracy, whether you need rolls, sheets, or custom shapes. We also offer surface treatments like lamination or fabric bonding to enhance functionality. At neoprenecustom.com, customization is our specialty.

What’s the last step before your neoprene sheets reach you? A final inspection ensures that every sheet meets your requirements and our quality standards. We check dimensions, surface quality, and performance characteristics one last time. Then, we carefully package the sheets to prevent damage during shipping. When you receive your order from neoprenecustom.com, you can be confident it’s ready for immediate use.

Why settle for off-the-shelf neoprene when you can have custom solutions? As a leading neoprene supplier, we specialize in creating high-quality neoprene sheets tailored to your unique needs. Our 7-step quality control process ensures that every sheet delivers unmatched performance, whether for wetsuits, industrial gaskets, or medical applications. Plus, our team is here to guide you through the customization process, from material selection to final delivery.

Ready to elevate your projects with premium neoprene sheets? Contact us today at kevin@neoprenecustom.com or visit neoprenecustom.com to discuss your requirements. We’re your trusted partner for custom neoprene manufacturing, delivering quality you can rely on.

Wondering where our neoprene sheets shine? Here are just a few examples:

No matter your industry, our custom neoprene sheets are designed to meet your needs with precision and reliability.

Why wait to experience the best in neoprene manufacturing? At neoprenecustom.com, we’re committed to delivering high-quality neoprene sheets that exceed your expectations. Our 7-step quality control process ensures every sheet is perfect, and our customization options make it easy to get exactly what you need. Email us at kevin@neoprenecustom.com or visit neoprenecustom.com to request a quote today.

Contact: Kevin

Phone: 13417385320

Tel: 0734-87965514

Email: kevin@neoprenecustom.com

Add: Intersection of Zhangjialing Road and Science and Technology Road, Guiyang Industrial Park, Guiyang Town, Qidong County, Hengyang City, Hunan Province./Dongguan Factory(Louvcraft): Building 3, No.363 Dongxing West Road Dongkeng, Dongguan.